Applications

Evergreen Aviation provides safety and efficiency to Airports worldwide through a large number of different applications.

The specific applications needed to increase safety and optimise operation time and maintenance, are different from airport to airport. Through close collaboration and counseling with Evergreen Aviation, the most advantageous solutions are found for the specific airport.

On this page, you can get a look closer on the solutions Evergreen Aviation offers airports worldwide.

If you would like to hear more, contact us and we will provide you with all the information and guidance you need.

For the contact page, click here.

Airport upgrade

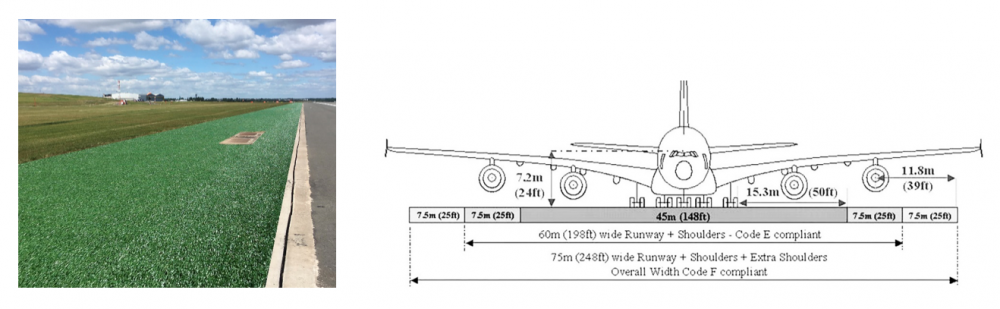

To operate the Airbus 380 and similar oversize aircrafts an airport amongst others has to comply with the Class F requirements. By means of AGAT, the airport category can be upgraded from class E to F.

Shoulders on RWY and TWY can be made wider without increasing the fortified area causing stagnant water on the runway after downpours.

It is possible to construct rainwater storage in the base building to control delay of surface water for derivation, reducing the pressure on the drainage system.

AGAT allows for overall wider TWY and RWY without increasing the fortified area, and at the same time the visual reference is increased and FOD clearly detectable.

AGAT advantages

-

Improved FOD elimination and recognition

-

Visual enhancement by narrowing the set down area while widening the paved area

-

Possible drainage true the surface to reduce standing water

-

Weir off sustainable

Installation

When installing AGAT along the runway edges the maintenance around signs, lamps and runway markings are drastically reduced. When installing artificial turf, the speed and possibility of detecting FOD increases and the number and length of incursions are minimized. The AGAT increases the visual reference of edges and secures against immersion at involuntary exits.

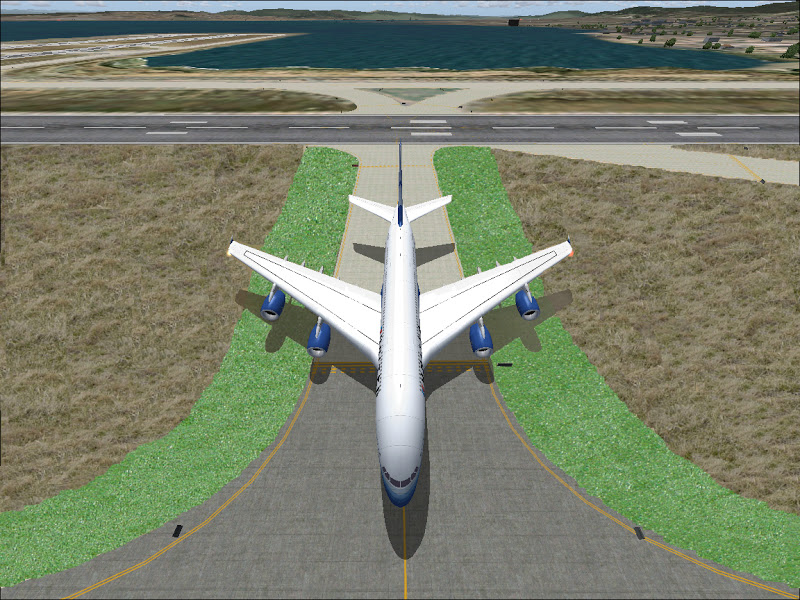

AGAT Runways (RWY)

Key facts

An RWY paved with AGAT gives the ideal surface to land small and medium size airplanes regardless of geographical and weather conditions:

-

Visual recognition of surface, lines, and markers regardless of the weather

-

FOD elimination and recognition to ensure maximal safety during taxi, warm up, start, landing, hot start, and engine braking

-

Immediate usage and instant repair.

-

Snow removable, with documented friction in dry and wet condition

-

Fire retardant, chemical resistant, flood proof, surface with documented friction on the entire surface, lines, and edges in all weather conditions.

-

Markings will be permanent and with the same friction and will have a distinct color difference regardless of natural light level and humidity.

Advantages

AGAT can be installed as runway surface for jets, propeller and hang gliders.

By landing on AGAT instead of natural grass, hazardous divots and soft spots, typically in touch down and taxi areas are prevented.

With AGAT on the RWY, an even surface is secured no matter the weather or season.

An even surface has a documented positive effect of the live expectancy of gear and fuselage.

FOD is not generated by the surface and FOD from outside the landing strip is easily detected.

AGAT and infill are environmentally neutral and can as such be used in sensitive areas. After end use, the infill can easily be absorbed in the natural environment and the carpet has an increasing scrap value, following the oil prices.

The durable AGAT reduces hazards and greatly improves the life expectancy of airplanes (vibrations during landing, ruts, and depressions can cause harm to airplane fiberglass, which is amplified on the natural grass landscape).

Tests

AGAT meet the specifications in FAA Advisory Circular 150/5370-15B and has been identified as a material that can be used to cover large portions of airport property with multiple benefits.

AGAT is extremely useful at work-areas with high load-bearing demands.

The artificial surface designed as a major safety improvement for the world’s airports improves visual delineation between movement areas and non-movement areas, solves water-pooling problems and controls erosion.

AGAT supports high-volume aircraft traffic traverse without rutting, soil transfer or other repair requiring damages.

In spite of ultra-heavy loads, including large aircraft, maintenance is kept at an absolute minimum.

AGAT achieves the highest performance standards in terms of airport ground safety in all critical areas.

Advantages of AGAT helipads:

No FOD and debris: Fast and safer start, stop, loading and unloading

Ideal visual reference: Safe straight approach and recognition of foreign object

Fueling: AGAT provides the safest possible surface to conduct fueling

No maintenance: Permanent markings and absorption of small particles

Snow clearing: No limits of snow removability without the use of chemicals

Dimensions:

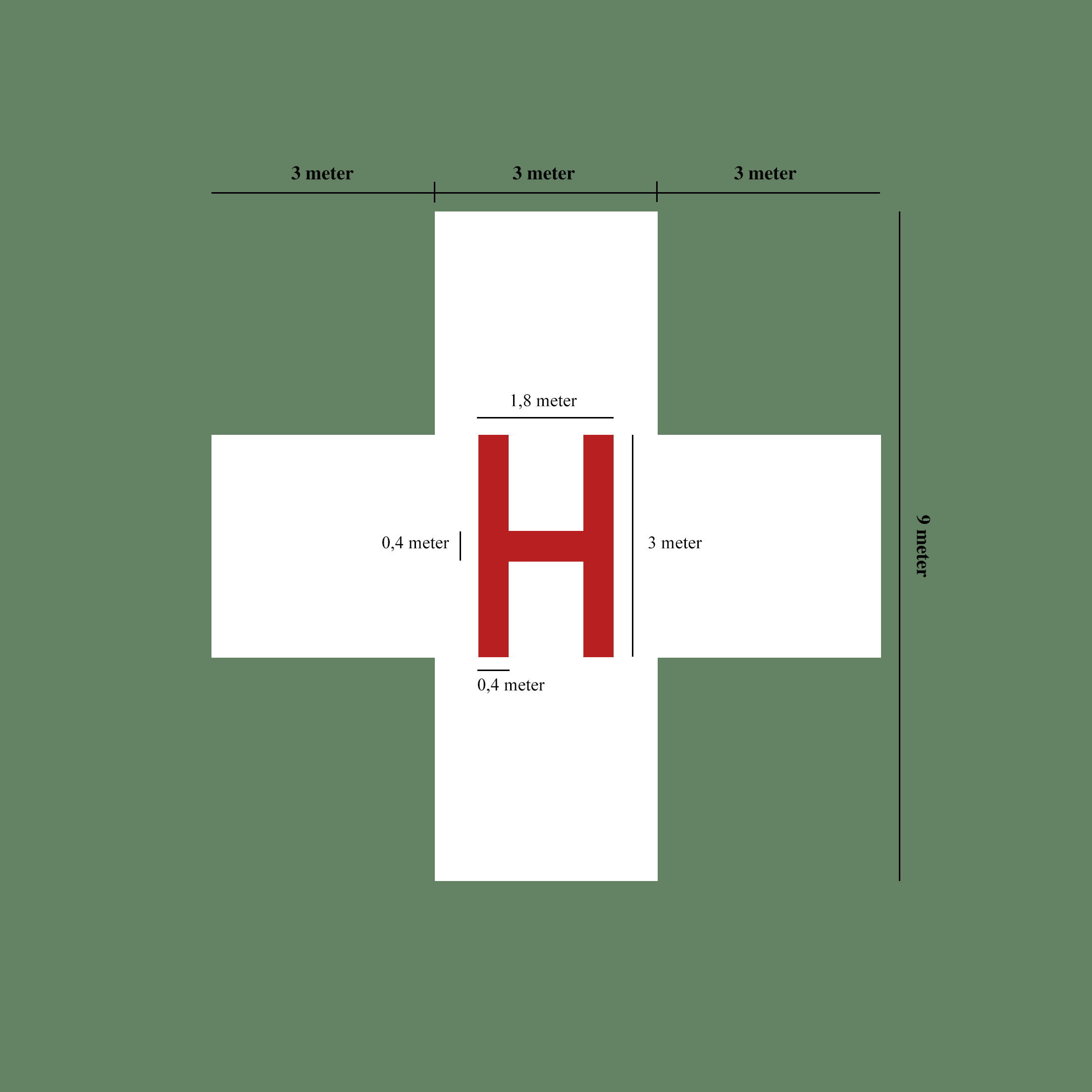

A helipad is dimensioned after the largest helicopter schedule for regular use. The Annex 14 describes the helipad size and markings. If local restriction dictates smaller sizes, consideration must be made by organizers and planners.

Installation:

AGAT is installed on a sub-base. The sub-base describes the maximum load bearing of the helipad in a worst-case scenario. It is typically not the helicopters weight but service vehicles like fire trucks, snow removal gear, fuel trucks, load and unload gear that determines the maximum load bearing on the helipad. Once the sub-base is established, the AGAT is rolled out.

AGAT is often installed on sub-base with an underestimated load bearing since it is easily repaired. Note that the surface will not break up or create FOD in case of a sub-base collapse.

The standard color of AGAT is green. Permanent markings are white for landing, yellow for taxi and red for service vehicles access, in accordance with Annex 14. Normally the green turf is installed first, and then the markings are cut in on site. If local condition dictates it, the entire AGAT surface can be produced off location and airlifted to its final destination.

After correct placement, the AGAT is fastened at the edges either by glue down or by trench and bury. The AGAT is filled with 25 kg of rounded sand pr. m² which is brushed into the fibers and the AGAT Helipad is ready for unlimited use.

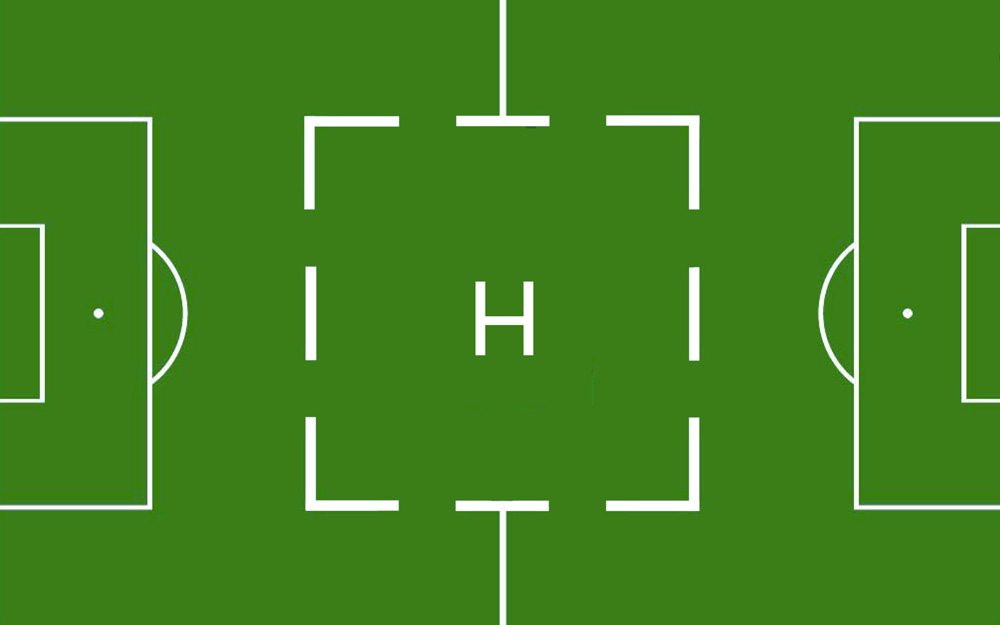

The Evergreen Heli Pitch

Useful combination of sports field and helipad.

Evergreen Aviation holds all officially certifications.

Installation on all surfaces, size according to local conditions, minimum goal 20 x 40 meters

Advantages

-

Usable all year

-

Full environmental considerate

-

Effective and refined sponsor signage

-

Quick but high delivery quality

-

Simple maintenance

Accessories

Field lines and helipad markings designed as needed. Provision of individual rail, security- and or sports-fence and lighting solutions. Integration of e.g. Weather Station and GPS track.

Heli-Pitch-skitse-Evergreen-Aviation-01052016

Security Fence

The bottom wire of security fences around airports is to be kept free of vegetation. This is done either by manual labour or with the use of pesticides.

When installing artificial grass under the fence and sufficiently on both sides, the use of pesticides and mowing is eliminated and the time spent inspecting is minimized.

Advantages

Regardless if it’s paved or natural areas, AGAT on the fueling area will contribute to improved safety, protection of the environment and enhanced nudging.

On AGAT rain and other fluids are collected and lead to the drain.

Sand infill in AGAT absorbs spills of fuel, oil, etc. and contaminated infill can easily be replaced. The sand infill works as a fire retardant in case of ignited spills on the ground.

AGAT is resistant towards all chemicals found in airports.

Resistance and absorption

AGAT absorbs the spill and is resistant to Propylene Glycol, Jet A, Diesel, Potassium Acetate, No Gel, Urea, Aviation Hydraulic Fluid, Glycol Type 1 – Orange, 100LL Fuel, Glycol Type 4 – Green.

Note: AGAT’s fire resistance is rated ‘excellent’ when tested in cooperation with the Airside Facilities Engineering Team at the Greater Toronto Airports Authority.

Advantages

Fast and safer start, stop loading and unloading. Ideal visual reference.

Safe straight approach and recognition of a foreign object.

AGAT provides the safest possible surface to conduct fueling

No FOD and debris. No maintenance.

Permanent markings and absorption of small particles

Snow clearing. No limits of snow removability without the use of chemicals. Smooth and even surface for stretcher and emergency vehicles.

Installation:

AGAT is installed on a sub-base. The sub-base describes the maximum load bearing of the helipad in the worst case scenario. It is typically not the helicopters weight but service vehicles like fire trucks, snow removal gear, fuel trucks, load and unload gear that determines the maximum load bearing on the helipad. Once the sub-base is established the AGAT is rolled out.

AGAT is often installed on sub-base with an underestimated load bearing since it is easily repaired. Note that the surface will not break up or create FOD in case of a sub-base collapse.

The standard color of AGAT is green. Permanent markings are white for landing, yellow for taxi and red for service vehicles access, in accordance with Annex 14. Normally the green turf is installed first, and then the markings are cut in on site. If local condition dictates it, the entire AGAT surface can be produced off location and airlifted to its final destination.

After correct placement, the AGAT is fastened at the edges either by glue down or by trench and bury. The AGAT is filled with 25 kg of rounded sand pr. m² which is collected into the fibers and the AV Helipad is ready for unlimited use.

Dimensions:

A helipad is dimensioned after the largest helicopter schedule for regular use. A heliport identification marking for a helipad at a hospital shall consist of a letter H, red in colour, on a white cross made of squares adjacent to each of the sides of a square containing the H as shown on the figure.

Instrument landing system (ILS)

ILS enables aircraft to land if the pilots are unable to establish visual contact with the runway. It does this by way of transmitted radio signals with horizontal and vertical guidance just before and during landing and, at certain fixed points, indicates the distance to the reference point of landing. ILS-areas are usually designed with a service road on both sides of the RWY-ends towards the security fence.

Advantages

-

The accessibility in emergency situations is guaranteed and the response time is reduced.

-

The accessibility by the maintenance of ILS equipment is improved.

-

The visual reference is optimized.

-

No use of resources and operation time for maintenance such as grass mowing, weed control and search for FOD are necessary.

-

By removing food, water, and shelter for all prey and insects, the number of birds will be drastically reduced and consequently, the security improved.

Installation

AGAT is easily installed on any surface and provides a major security improvement because the synthetic turf prevents disturbance and interference by reducing incursion, like lawn mowing, weeds, etc. The ground area covered with AGAT requires absolute minimal supervision and maintenance.

Installation

Installing AGAT at intersections gives a clear visual reference of the runway limits. Problem free installation regarding current devices such as signs, fences, and lamps.

Advantages

A strong base covered with AGAT provides a maximal load-bearing capacity, strong enough for heavy vehicles, to run over without sinking in – even aircraft that by accident cuts corner with the inner wheel.

Additionally AGAT coating significantly reduces maintenance and thereby minimizes both number and lengths of incursions regarding the intersection areas.

Increases the visual reference of edges and secures against immersion at involuntary exits.

Islands

Airport islands mounted with AGAT improves the visual reference between the paved areas and the inoperative areas where planes are unwanted, which enhance vehicle operators and pilots to maintain situational awareness while moving on the airport surface.

Advantages

Cost-benefit analyses, evaluating the construction expenditures against increased safety, increased esthetics, and reduced operating expenses, presents the many AGAT advantages. Incursion reduction is e.g. the result of the low maintenance.

The nudging effect of AGAT airport islands is remarkable.

In order to secure the optimal use of the island’s potential, Evergreen Aviation recommends AGAT groundcover so that emergency vehicles can rely on accessibility irrespective of area and use.

AGAT installations when security is a priority

AGAT is a highly recommended solution to ensure the right conditions around the various airport ground signal device.

Airport lamps are extremely vulnerable to planting. It is of utmost importance that all airport marking equipment is kept free of any disturbance that may interfere with the functionality.

Installation of AGAT in accordance with the existing equipment is trouble-free

Advantages

Artificial turf around runway lamps ensures low maintenance and thereby a significant incursion reduction regarding length and number.

Installation of artificial turf beneath runway markings and around lamps prevents e.g. weed blocking visual signals.

With AGAT FOD is easily detected and the clear overview and uninterrupted access provide easy supervision.

PAPI

Precision Approach Path Indicator (PAPI) is an aviation lighting system guiding pilots to a safe and accurate vertical approach to an airfield.

PAPI consists of four sets of lights in a line, usually mounted to the left side of the runway. Most large airports use this system.

AGAT advantages

AGAT has economical affordability when it comes to lighting upgrade.

Innovative without interfering with any of the airport’s legacy systems worthy of preservation.

The sturdy and reliable stable ground cover prevents disruptive and dangerous blockage and increases airfield lighting usage.

AGAT creates a sharp contrast that increases visibility.

Clear overview and easy accessibility for light maintenance.

The stability of this ground device is of the highest priority. AGAT secures that no incursion disturbances, like lawn mowing, weeds, etc, will interfere with the auxiliary signal tool that assists pilots in landing airplanes in airports.

Installation

Increasing airfield lighting utilization is a relatively simple intervention when mounting AGAT.

AGAT is easy to align and adaptable to individual specs design, airfield requirement, and modification needs.

When installing AGAT around PAPI, mowing and weed control is not necessary and consequently, the risk of damaging lamps and the electrical installation is eliminated and incursions and risks of operation stops will be reduced. AGAT is easily installed around existing lamps, signs or other device systems. Security wise AGAT is a significant benefit regarding airport ground device.

Airport upgrade

AGAT marking strips with standardized airport direction and identification to all air and ground crews.

Clear airfield markings are important— both for air and ground personnel. AGAT markings can improve visual reference in various ways and appeals to those who give the airport industry safety the utmost concern.

AGAT advantages

AGAT allows markings to be embedded right into the turf.

AGAT is formulated for long life despite the exposure to hard weather and sun. Markings do not fade and stand bright and visible throughout the whole lifetime.

Especially inaccessible airports, smaller airstrips, and sailplanes runways benefit from AGAT full visual runways with incorporated markings.

Service Areas

Larger airports provide many services that result in multi-surface use. Different user groups are accessing airfield ground for various purpose.

Control and guidance related to this activity are of high importance.

AGAT improves the general ground access indication. The great nudging potential easily indicates where e.g. passenger, luggage transport, cargo or airline/airport employees origins and destinations occur.

AGAT covered service areas are tailored to each airport’s needs and capabilities according to the services the airport wish to offer.